Training

Here are some examples of the training offered at the Creative Education Center.

Web Syllabus

Rod Paperweight Production

In the 2nd year manufacturing training, students make a rod paperweight in the machine finishing workshop. Originally a metal rod, the base is made flat using a vertical milling machine, and the knob is shaped with different diameters in the head and thread sections using a precision lathe. The knob's chamfering is also done using a precision lathe. A drilling machine is used to make holes in the base, and threading is done using taps and dies.

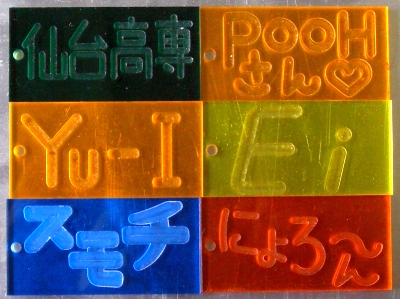

Name Plate Production

In the 2nd year manufacturing training, students also use computers to create designs in the NC working room. Students create drawings with CAD/CAM, program them, and run simulations. Based on these, the machining center automatically processes the materials. In this training, you can create a nameplate with your preferred design.

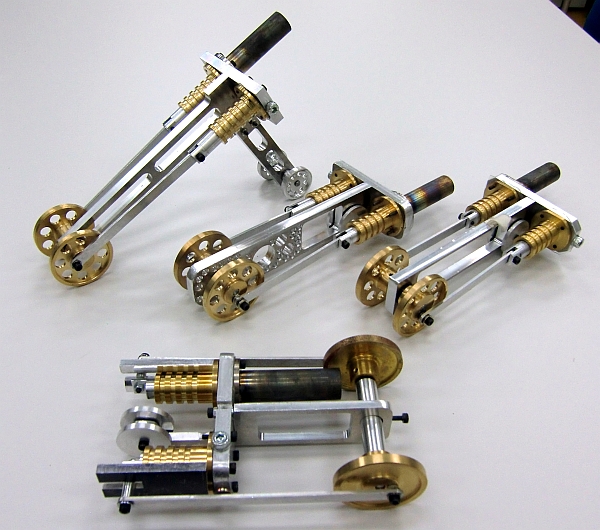

Model Stirling Engine Car

In the 3rd year of the Mechanical & Energy course, students engage in more advanced manufacturing. Using the drawings created in the design drafting course, students work in teams, each group responsible for different parts of the project. They produce, assemble, adjust, and test the model. Manufacturing is done using a lathe, milling machine, NC machines, and hand-finishing. The completed models are then used in a competition where their performance and distance covered are measured.